Methodology for testing the electrical parameters of low-voltage foil

Measuring capacitance

- Place the molded foil sample in a measuring cell with electrolyte in such a way that only the working part of the sample (without the terminal) is immersed in the electrolyte;

- Keep the sample for 1 minute, then measure the capacity;

- The capacitance value obtained from the device is divided by 10 to obtain the specific capacitance value in μF/dm2.

Methodology for testing electrical parameters of high-voltage foil

1.1 Forming etched foil samples for subsequent forming in electrolyte No. 4

1.2 Forming etched foil samples for subsequent forming in electrolyte No. 1

Hydration

- Time: 15±1 minute;

- Temperature: ≥ 95°C;

- Number of samples: ≤ 6;

- Replace deionized water: after each hydration process.

Forming electrolyte

Forming stage 1:

- Boric acid - 100 g;

- Deionized water (≤ 0.1 μS/cm) — 900 ml.

Forming stage 2:

- Boric acid - 100 g;

- Ammonium pentaborate, tetrahydrate — 0.7 g;

- Deionized water (≤ 0.1 μS/cm) — 900 ml;

Forming parameters

- Forming current - 0.5 A/sample;

- Electrolyte temperature is 90±2°С.

Forming parameters

The test sample should be immersed in the electrolyte so that the top of the measured sample is 10-15 mm below the surface of the solution.

Forming electrolyte

- Citric acid - 2 g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte resistance at + 30ºС is 1000 ± 50 Ohm×cm.

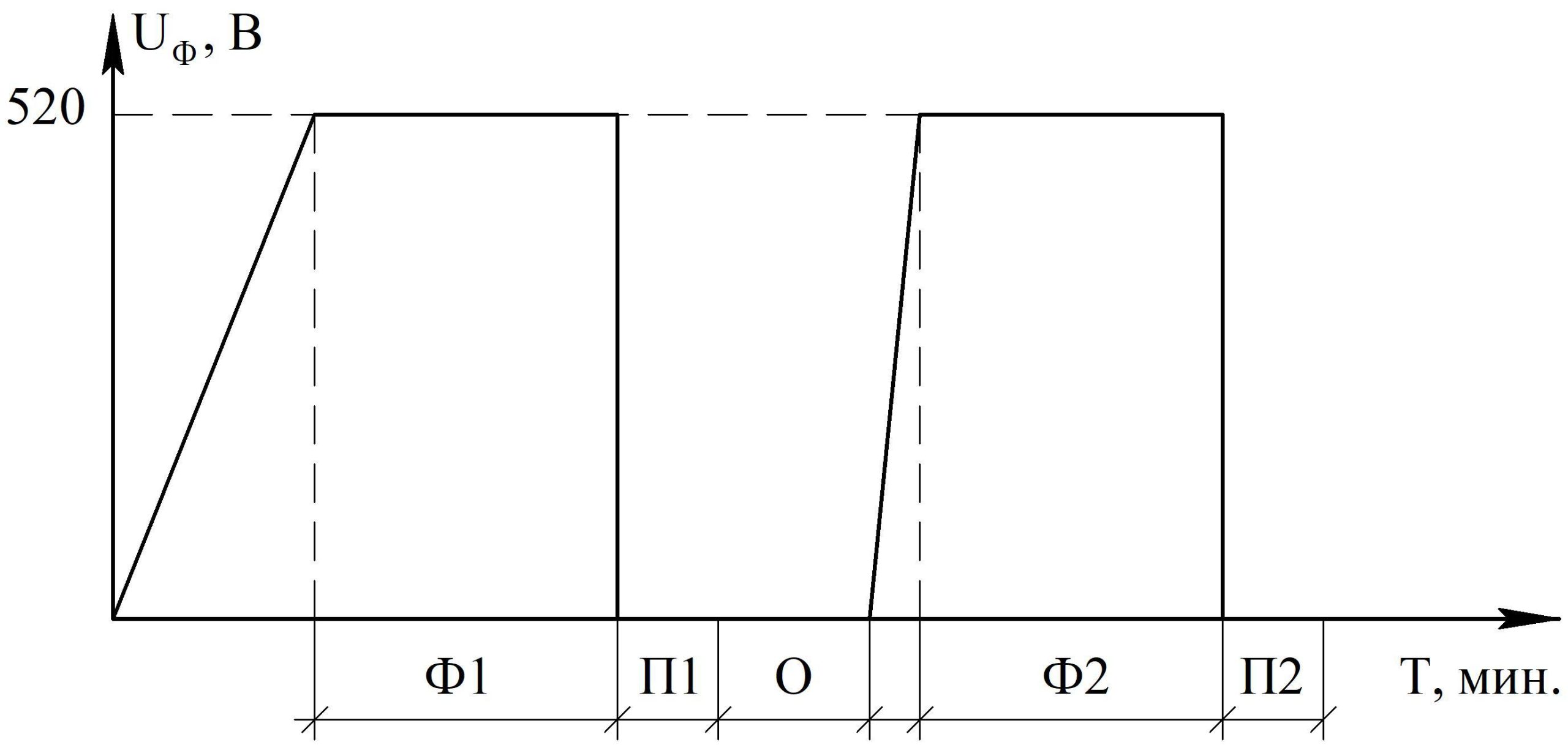

Molding scheme

– Forming cycle F1 – 10 minutes;

– Rinse (P1) – 1 minute;

– Annealing from +510 to +530°C (O) – 2 minutes;

– Forming cycle (F2) – until the forming current drops to 0.03 A;

– Rinse (P2) – 1 minute.

Flushing

Samples are washed in deionized water at room temperature.

Drying

Drying of samples is carried out at a temperature of < 100°C.

2. Measuring forming stress

Test equipment

-

DC power supply

- ripple ≤ 1%;

- voltage stability ± 3%; - DC voltmeter - accuracy ± 0.5%;

- DC ammeter - accuracy ± 1.0%;

- Stainless steel bath, temperature control.

Electrolyte for voltage measurement

Forming voltage from 200V to 620V:

- Boric acid - 70g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 7,500 ± 300 Ohm×cm.

Forming voltage from 621V to 700V:

- Boric acid - 40g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 19,000 ± 1,000 Ohm×cm.

Forming voltage from 701V to 800V:

- Boric acid - 30g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at +70ºС — 28,900 ± 1,500 Ohm×cm.

Forming voltage above 800 V:

- Boric acid - 20g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 46,500 ± 2,500 Ohm×cm.

Measuring capacitance

- Place the molded foil sample in a measuring cell with electrolyte so that only the working part of the sample (without the terminal) is immersed in the electrolyte;

- Keep the sample for 1 minute, then measure the capacity;

- Multiply the capacitance value obtained from the device by 10 to obtain the specific capacitance value in μF/dm2.

4. Control of oxide layer stability

Electrolyte for voltage measurement

Forming voltage from 200V to 620V:

- Boric acid - 70g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 7,500 ± 300 Ohm×cm.

Forming voltage from 621V to 700V:

- Boric acid - 40g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 19,000 ± 1,000 Ohm×cm.

Forming voltage from 701V to 800V:

- Boric acid - 30g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at +70ºС — 28,900 ± 1,500 Ohm×cm.

Forming voltage above 800 V:

- Boric acid - 20g;

- Deionized water (≤ 0.1 μS/cm) - 1000 ml;

- Electrolyte conductivity at + 70ºС — 46,500 ± 2,500 Ohm×cm.

Methodology for testing the electrical parameters of cathode foil

Electrolyte for measuring capacity

- Ammonium adipate - 150 g;

- Deionized water (≤ 0.1 μS/cm) – 1000 ml;

- Сопротивление электролита, при + 70°С — 5,0 … 8,5 Ом×см.

Multiply the capacitance value obtained from the device by 20 to obtain the specific capacitance value in μF/dm2

Stabilization quality control

Electrolyte for measuring capacity

- Ammonium adipate - 150 g;

- Deionized water (≤ 0.1 μS/cm) – 1000 ml;

- Electrolyte resistance at + 70°C is 5.0 … 8.5 Ohm×cm.

Bending test method

Test conditions

Foil type | Bending radius, mm |

|---|---|

| Etched anode high voltage | 0,5 ± 0,05 |

| Molded anode low voltage | 0,5 ± 0,05 |

| Molded anode high voltage | 0,5 ± 0,05 |

| 3,5 ± 0,35 | |

| Cathodic etched | 1,0 ± 0,10 |

| Cathode annealed |