Procedure of checking electrical parameters of low voltage foils.

Test procedure:

- Forming of etched foil specimens

- Measurement of forming voltage

- Capacitance measurement

- Oxide layer stability control

1.

Forming of etched foil specimens

Testing equipment

-

DC power supply

- Ripples ≤ 1%

- Voltage stability ± 3% - DC voltmeter — Accuracy ± 0.5%

- DC ammeter — Accuracy ± 1.0%

- Stainless steel tank, temperature control

Specimen size

Specimen length (L) is set by equipment.

The edges of the specimen must be perfectly cut without tears and burrs.

Forming electrolyte

- Ammonium adipate — 150 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at +70°С — 5.0 … 8.5 Ω×cm

- рН, at + 50°С — 5.2 … 7.2

Forming conditions

- Forming current — 0.3 А/specimen

- Electrolyte temperature — 70 ± 2°С

Forming

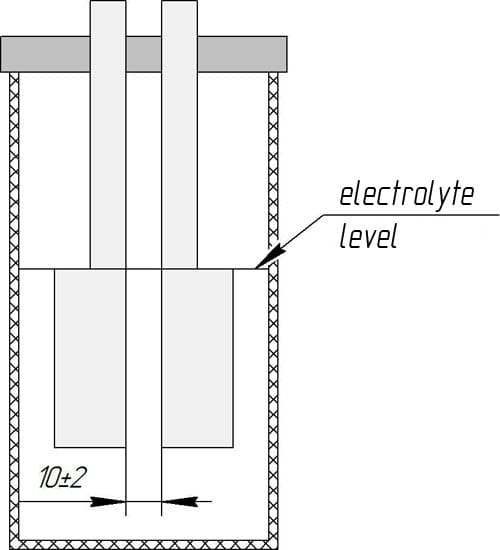

The specimen is put in the electrolyte so that the upper part of the specimen is 10 … 15 mm below the solution surface.

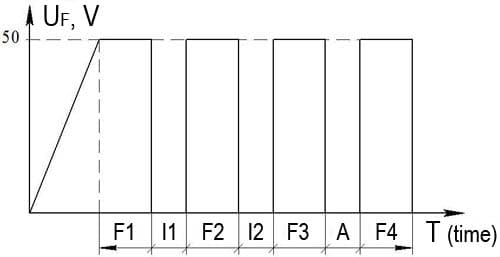

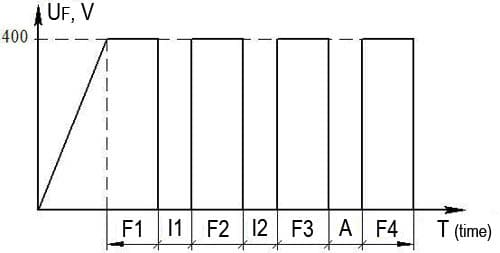

Forming procedure

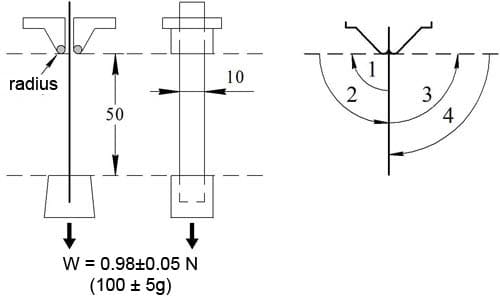

- Forming cycle (F1; F2; F3; F4) — 6 minutes

- Interval between forming cycles (I1; I2) — 1 minute

- Annealing 530°С (A) — 1 minute

Rinsing

Specimens shall be rinsed in de-mineralized water at room temperature.

Drying

Specimens shall be dried at the temperature < 100°C.

2.

Forming voltage measurement

Testing equipment

-

DC power supply

- Ripples ≤ 1%

- Voltage stability ± 3% - DC voltmeter — Accuracy ± 0.5%

- DC ammeter — Accuracy ± 1.0%

- Stainless steel tank, temperature control

Electrolyte for measuring the voltage

- Ammonium adipate — 150 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 70°С — 5.0 … 8.5 Ω×cm

- рН, at + 50°С — 5.2 … 7.2

Electrolyte parameters

- Control current — 2.0 ± 0.2 mA/specimen

- Electrolyte temperature — 70 ± 2°С

Voltage measurement

The specimen is put in the electrolyte so that the upper part of the specimen is below the solution surface.

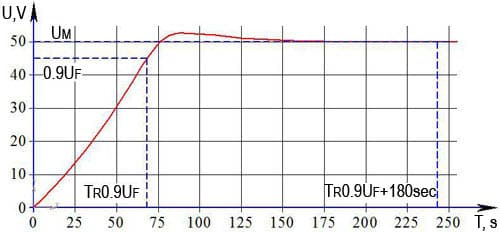

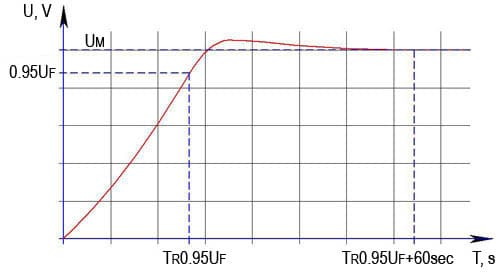

Voltage scheme

To check time to reach 0.9×UF and maximal voltage (UM) in 180 seconds after TR0.9×UF

3.

Capacitance measurement

Testing equipment

- Capacitance meter — accuracy ± 1%

- Measurement frequency — 100 Hz ± 5% (acceptable 50 Hz)

- Cell from inert materials

- Counter electrode - etched thermo-oxidized foil with capacitance of ≥ 400 µF/cm²

Electrolyte for measuring the voltage

- Electrolyte Ammonium adipate — 150g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at +70°С — 5.0 … 8.5 Ω×cm

- Electrolyte temperature — 20 … 25°С

Capacitance measurement

- formed foil specimen is to be put in a measurement cell with electrolyte so that in electrolyte solution was only the working part of the specimen (without leads)

- keep the specimen in for one minute, then capacitance should be measured

- to get specific capacitance value (µF/cm²) divide the value received from the meter by 10

4.

Oxide layer stability control

Test specimen

Formed foil specimen passed tests according to p. 2 and 3

Hydration

- Time: 60 ± 1 minutes

- Temperature: ≥ 95°С

- Number of specimens: ≤ 6

- Replacement of de- mineralized water: after each process of hydration

Electrolyte for measuring the voltage

- Ammonium adipate — 150 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 70°С — 5.0 … 8.5 Ω×cm

Electrolyte parameters

- Control current — 2.0 ± 0.2 mA/specimen

- Electrolyte temperature — 85 ± 2°C

Voltage measurement

- Put the test specimen into electrolyte so that the top edge (is to be measured) was on the surface

- >Measure the time to reach 0.9UF

Procedure of checking electrical parameters of high voltage foils.

Test procedure:

- Forming of etched foil specimens

- Measurement of forming voltage

- Capacitance measurement

- Oxide layer stability test

1.

1. Forming of etched foil specimens

Testing equipment

-

DC power supply

- Ripples ≤ 1%

- Voltage stability ± 3% - DC voltmeter — Accuracy ± 0.5%

- DC ammeter — Accuracy ± 1.0%

- Stainless steel tank, temperature control

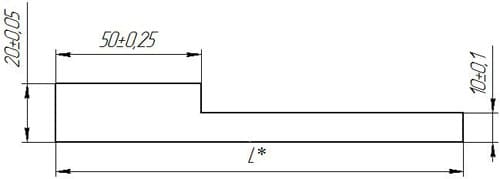

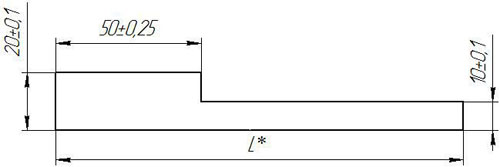

Specimen size

Specimen length (L) is set by equipment.

The edges of the specimen must be perfectly cut without tears and burrs.

Forming electrolyte

- Citric acid — 2 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 30°С — 1000 ± 50 Ω×cm

Forming conditions

- Forming current — 0.5 А/specimen

- Electrolyte temperature — 90 ± 2°C

Forming

The specimen is put into the electrolyte so that the upper part of the specimen is 10-15 mm below the solution surface

Forming procedure

- Forming cycle (F1; F2; F3; F4) — 10 minutes

- Interval between forming cycles (I1; I2) — 2 minutes

- Annealing 250°С (A) — 2 minutes

Rinsing

Specimens shall be rinsed in de-mineralized water at room temperature.

Drying

Specimens shall be dried at the temperature < 100 °С

2.

Forming voltage measurement

Testing equipment

-

DC power supply

- Ripples ≤ 1%

- Voltage stability ± 3% - DC voltmeter — Accuracy ± 0.5%

- DC ammeter — Accuracy ± 1.0%

- Stainless steel tank, temperature control

Electrolyte for measuring the voltage

Forming voltage from 200 V to 600 V:

- Boric acid — 70 g

- De-mineralized water (≤ 0.1 µS/cm) - 1000 ml

- Electrolytic conductivity, at + 70°С - 0.132 mS/cm ± 5%

Forming voltage over 600 V:

- Boric acid — 50 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolytic conductivity, at + 70°С — 0.077 mS/cm ± 5%

Electrolyte parameters

- Control current — 4.0 ± 0.2 mA/specimen

- Electrolyte temperature — 90 ± 2°С

Voltage measurement

The specimen is put into the electrolyte so that the upper part of the specimen is below the solution surface

Voltage scheme

To check time to reach 0.95×UF and maximal voltage (UM) in 60 seconds after TR0.95×UF

3.

Capacitance measurement

Testing equipment

- Capacitance meter — accuracy ± 1%

- Measurement frequency — 100 Hz ± 5% (acceptable 50 Hz)

- Cell from inert materials

- Counter electrode — etched thermo-oxidized foil with capacitance of ≥ 400 µF/cm²

Electrolyte for measuring the capacitance

- Ammonium adipate — 100 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 20°С — 16 … 20 Ω×cm

Electrolyte parameters

Electrolyte temperature — 20 … 25°С

Capacitance measurement

- formed foil specimen is to be put in a measurement cell with electrolyte so that in electrolyte solution was only the working part of the specimen (without leads)

- keep the specimen in for one minute, then capacitance should be measured

- to get specific capacitance value (µF/cm²) divide the value received from the meter by 10

4.

Oxide layer stability control

Test specimen

Formed foil specimen passed tests according to p. 2 and 3.

Hydration

- Time: 60 ± 1 minutes

- Temperature: ≥ 95 °С

- Number of specimens: ≤ 6

- Replacement of de-mineralized water: after each process of hydration

Electrolyte for measuring the voltage

Forming voltage from 200 V to 600 V:

- Boric acid — 70 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolytic conductivity, at + 70°С — 0.132 mS/cm ± 5%

Forming voltage over 600 V:

- Boric acid — 50 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolytic conductivity, at + 70°С — 0.077 mS/cm ± 5%

Electrolyte parameters

- Control current — 4.0 ± 0.2 mA/specimen

- Electrolyte temperature — 90 ± 2°С

Voltage measurement

- Put the test specimen into electrolyte so that the top edge (is to be measured) was on the surface

- Measure the time to reach 0.95UF

Procedure of checking electrical parameters of cathode foils.

Test procedure:

- Capacitance measurement

- Oxide layer stability test

1.

Testing equipment

- Capacitance meter — accuracy ± 1%

- Measurement frequency — 100 Hz ± 5% (acceptable 50 Hz)

- Cell from inert materials

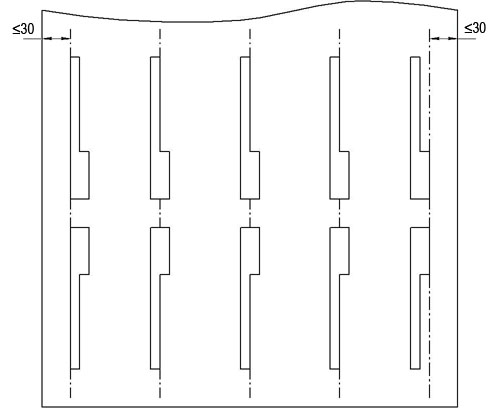

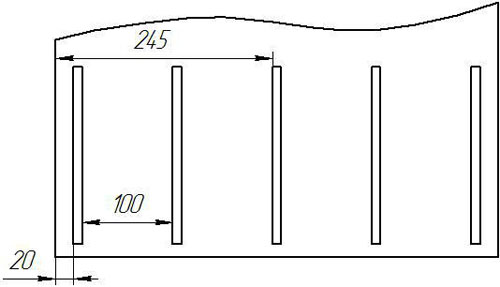

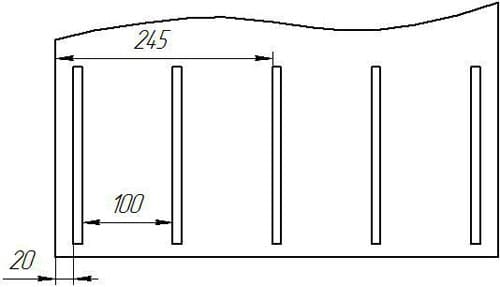

Sampling procedure

Specimen size

Specimen length (L) is set by equipment.

The edges of the specimen must be perfectly cut without tears and burrs.

Electrolyte for measuring the capacitance

- Potassium nitrate — 101 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 20°С — 15 … 20 Ω×cm

Electrolyte parameters

Electrolyte temperature — 20 … 25 °С

Capacitance measurement

- two controllable foil specimens (arranged one above another according to the sampling procedure) are to be put in a measurement cell as shown in the picture

- keep the specimens in for one minute, then capacitance should be measured

- to get specific capacitance value (µF/cm²) divide the value received from the meter by 10

2.

Oxide layer stability test

Test specimen

Foil test specimens that meet standards according to test no. 1.

Hydration

- Time: 30 ± 1 minutes

- Temperature ≥ 95 °С

- Number of specimens: ≤ 6

- Replacement of de- mineralized water: after each process of hydration

Electrolyte for measuring the capacitance

- Potassium nitrate — 101 g

- De-mineralized water (≤ 0.1 µS/cm) — 1000 ml

- Electrolyte resistance, at + 20°С — 15 … 20 Ω×cm

Electrolyte parameters

Electrolyte temperature — 20 … 25°С.

Capacitance measurement

Measure the specific capacitance according to the p. 1.

Residual chloride test method.

Equipment and devices

- Heating plate

- Cooling tank

- Beakers, bottles, burettes, pipettes when necessary

Chemical agents

- Nitric acid 65%, chemically pure

- Silver nitrate, analytically pure

- De-mineralized water (≤ 0.1 µS/cm)

Test specimen

Nominal area 0.1 m² (two sides surface), cut into strips of 20 … 25 mm width

Test method

- Strips are wrapped in loosely rolls, put in a test tube and poured with 100 ml of 5% nitric acid solution

- Test tube is heated in water bath to temperature of 40 … 45°C, keep 10 minutes, stirring with the glass rod

- Rolls are removed from the solution. Then the solution has to be cooled down

- The solution is filtered to absolute transparency

- Add 10 drops of 5% silver nitrate solution to the test solution and to standard scale solutions

- In 10 minutes compare the opalescence of the test solution to the opalescence of standard scale solutions

Bending strength test method.

Equipment

Installation of bending counter

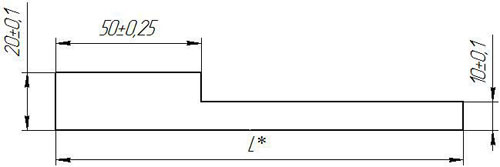

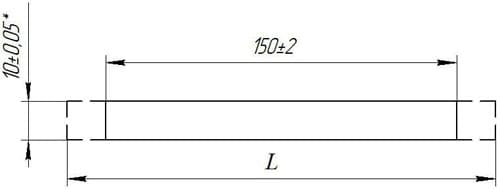

Sampling procedure

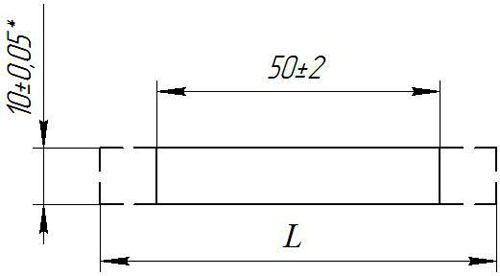

Test specimen

*

Size is set by equipment

L – is set by equipment used

Test conditions

| Foil type | Bending radius, mm |

|---|---|

| Etched foil | 0.5 ± 0.05 |

| Formed low voltage foil | 0.5 ± 0.05 |

| Formed high voltage foil | 3.5 ± 0.35 |

Test method

— One bend is one 90 degree turn

— The test ends when the foil specimen breaks

Tensile strength test method.

Equipment

Tensile-testing machine, measurement range: force — from 0 to 500 N, measuring error – max 1%, speed of movable clamp – 50 – 60 mm/min.

Sampling

Test specimen

*

Size is set by equipment

L – is set by equipment used

Test method

To determine ultimate tensile strength the test specimen is charged with tensile load (tensile force) until it breaks. When the specimen breaks at the point of clamping, the test shall not be counted and shall be carried out on another specimen.